3rd Generation Raketa Track Hubs

Innovation meets Excellence

Since track racing is not the most popular segment of cycling, most manufacturers don’t pay much attention to it. And as a result, most track products on the market have outdated design and are built using old techniques. In 2019, we already tried to break this tendency with the second generation of our track hubs, and now we’re happy to present you the 3rd Generation of Raketa Track Hubs — the product where Innovation meets Excellence.

With the 3rd Generation of Raketa Track Hubs, we've poured our passion and 7 years of expertise into creating a product that redefines the standards of track racing. We've refined every detail, employing cutting-edge design and implementing the latest manufacturing techniques to ensure these hubs are at the forefront of performance and reliability. We have redesigned the hubs from scratch, making them completely new internally, but kept their unique visual appearance.

Internals. What has changed

Smart machining for lower weight

At Raketa, we've harnessed the power of advanced machining techniques to bring you hubs that are built for optimal weight reduction. Each hub is meticulously crafted from aerospace-grade 7075-T651 aluminum, chosen for its exceptional strength to weight ratio. This results in hubs that are not only impressively lightweight but also incredibly robust, making them an essential component for any track bike.

But we didn't stop there. Through the application of special tools, we've further reduced the weight by eliminating excessive material from the hub shell's interior. This precise machining process ensures that every gram counts and delivers a sleeker, more streamlined design. Experience the power of smart machining firsthand - choose our revolutionary hubs for an unparalleled cycling experience.

Always perfect preload - no hassle with the preload adjustment

We understand the challenges that come with achieving the perfect preload on the bearings of a rear track hub. The hub endures stress from tightly secured cogs and lockrings, while the axle can be deformed by the nuts or bolts used to secure the wheel in the dropouts. Although these deformations may not be visible, they have a significant impact on bearing performance.

Unlike many hubs that rely on preload collars or locknuts, which can be cumbersome to adjust, our 3rd generation track hubs feature a revolutionary bearing preload system known as "Always perfect preload". Developed based on cutting-edge principles, this system involves precision machining with tolerances as low as 0.005 mm (0.0002 inch). We've taken the hassle out of preload adjustment, ensuring that your bearings are always perfectly set for optimal performance, providing you with a smoother, hassle-free ride.

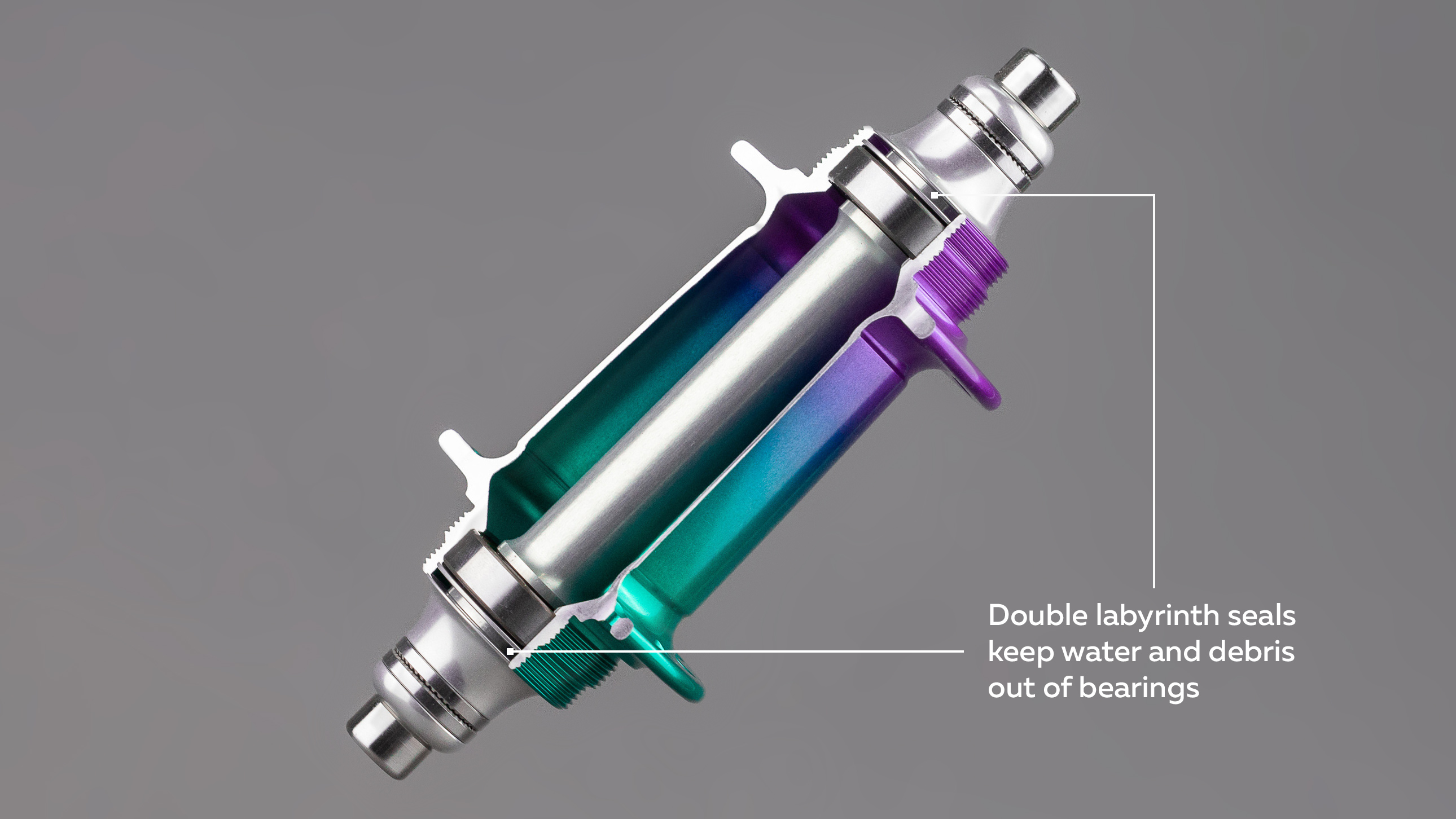

Double labyrinth seals on both hubs - better durability

We know that many of our customers use their track bikes on the streets, so we wanted to offer some additional durability. In our 2nd generation hubs, we included end caps with single labyrinth seals. Now, to enhance the longevity of our hubs, we've added a second layer of protection with double labyrinth seals on all four bearings. The beauty of labyrinth seals lies in their non-contact design, ensuring that your speed is not compromised while maximizing the bearings' performance and lifespan. Ride with confidence, knowing that your bearings are built to go the distance.

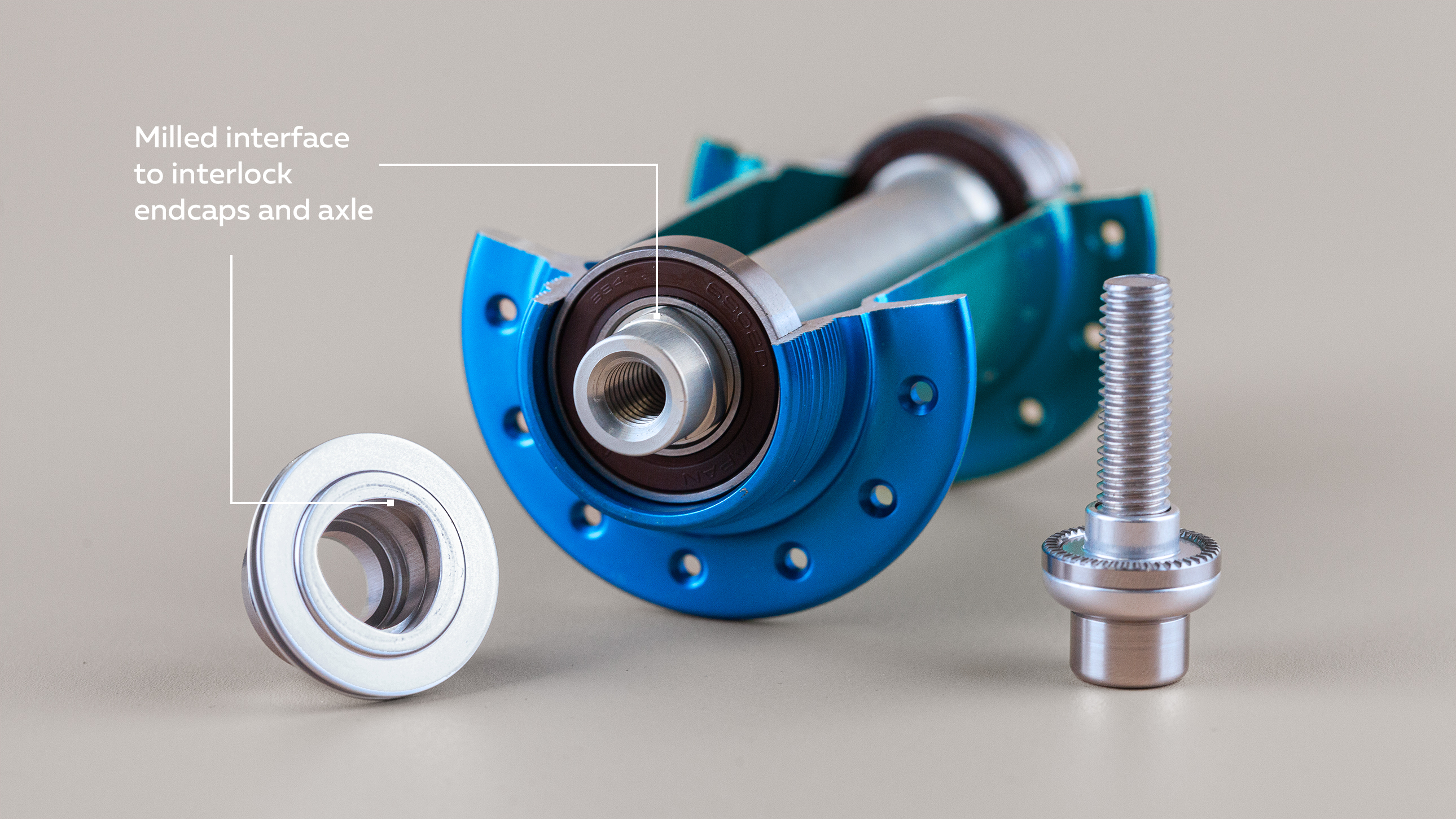

Endcaps with Anti-rotation system - easier wheel mounting

We've listened to your feedback and understand the challenges faced during wheel installation. While track hubs are secured by bolts or nuts rather than thru-axles, it's common for end caps on most track hubs to spin or become loose when fitting or removing the wheel. This can lead to various difficulties, such as wheels getting stuck, the need for an additional wrench, or even requiring readjustment of the preload. We wanted to make sure our customers never have to face these issues.

To address this, we've integrated an innovative Anti-rotation system into the endcaps of our hubs. This feature ensures that the endcaps remain securely in place at all times, making wheel mounting a breeze. Our axle assembly behaves like a solid unit, providing stability and ease of serviceability without the need for special tools. Enjoy hassle-free wheel installation and focus more on the ride itself.

Quality NSK bearings + bigger bearings in front hub

When it comes to the heart of our hubs, only the best will do. Inside every Raketa hub, you'll find NSK industrial sealed bearings, manufactured by a renowned Japanese company famous for producing some of the smoothest bearings in the world. With their exceptional seals, top-notch materials, and unparalleled build quality, we firmly believe that these bearings outperform any others in real-world cycling conditions.

For our 3rd generation front hubs, we've taken durability to another level. We've equipped them with larger 6902 bearings, a significant upgrade from the commonly found 6800 series bearings in front bicycle hubs. This enhancement greatly reinforces their longevity and ensures a smoother, more reliable ride. Experience the pinnacle of bearing quality and reliability with Raketa hubs - where innovation meets excellence.

Exterior

We've always been working hard to improve our manufacturing techniques and make our product even better through small, continuous improvements. With the 2nd generation of our hubs, we've reached the highest level of visual quality possible and we wanted to incorporate all of these advancements into our new hubs. At this point, we're confident that no other manufacturer in the world can match our superior build quality.

10 signature colors

We offer our hubs in a range of 10 signature anodized colors available all year round. What sets us apart is that we operate our own anodizing line, allowing us to anodize hubs in smaller batches thereby offering more color options.

Hand-polished hub shells

Each hub shell is individually hand polished to achieve the deepest color among all bicycle components worldwide. Our surface preparation methods, backed by our expertise, also contribute to a stronger outer layer of aluminum, enhancing the fatigue resistance of the alloy.

Carefully chamfered spoke holes for better spoke head placement

The spoke holes on our hubs are carefully chamfered from both sides using our precision CNC machines. This ensures perfect spoke head placement. Our chamfers have uniform size and are free from burrs, enabling hassle-free use of rope-type spokes like Berd Spokes, without requiring any additional chamfering.

Hardened steel washers

To guarantee a secure rear wheel fit in the dropouts, our rear track hubs are equipped with two-piece endcaps featuring sharp hardened stainless steel washers at the ends. We subject these small components to a heat treatment process to ensure their durability over numerous wheel installations.

Attention to every single detail

At Raketa, we give every aspect of our products the attention it deserves. We care for each surface, chamfer every edge, precisely control every dimension, and thoroughly inspect every fine detail at least twice. We take pride in the quality of our work and consider it a mark of excellence, making Raketa products unrivaled in the bicycle world.

Custom anodizing

For those seeking a truly exceptional hub set, we offer the option of custom multicolor anodizing. This process not only makes your hubs stand out but also catches attention both at shows and on the streets, ensuring that your bike will be unlike any other.

| Front hub | Rear hub | |

|---|---|---|

| Weight (without bolts) | 135 grams | 180 grams |

| Weight (including bolts) | 170 grams | 220 grams |

| Frame spacing | 100 mm | 120 mm |

| Bearings | 2x NSK 6902 | 2x NSK 6902 |

| Cog thread | 1,37"x24TPI | |

| Lockring thread | 1,29"x24TPI (LH) | |

| Rider weight limit | 100 kg | 100 kg |

| Bolts | Stainless steel, M8x30, 6mm hex | Stainless steel, M8x35, 6mm hex |

| Spoke hole drilling availability | 16, 18, 20, 24, 28, 32 | 20, 24, 28, 32 |

| Warranty | 5 years | |

| User manual | Download | |

| Dimensions (for wheel building) | Download |

Visit our online shop to order your Raketa Hubs